Knot Your Average Radio Station

The world is hungry for wood. BC harvests and exports logs and other fresh lumber but if the wood itself is hungry, there’s the problem.

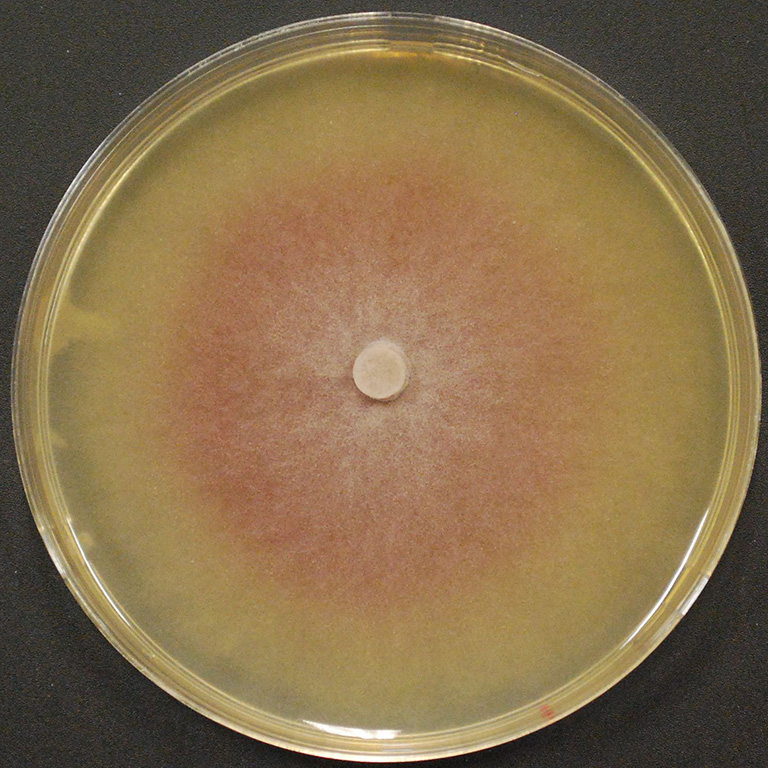

It’s not the moisture in the wood; it’s what rides along in the wet. Fungi, bacteria, insects and nematodes, billions of microorganisms: each ‘bug’ is a potential threat to BC’s crucial $7.6-billion (2013) export markets.

Set up under the UN Food and Agriculture Organization (FAO), the International Plant Protection Convention is designed to prevent the global spread of plant disease and pests. No one wants a repeat of the Dutch elm disease, in any form or from anywhere.

If BC is to keep selling wood, our exports must be ‘bug’ free. So how to efficiently and utterly phyto-sanitize streams of logs and lumber?

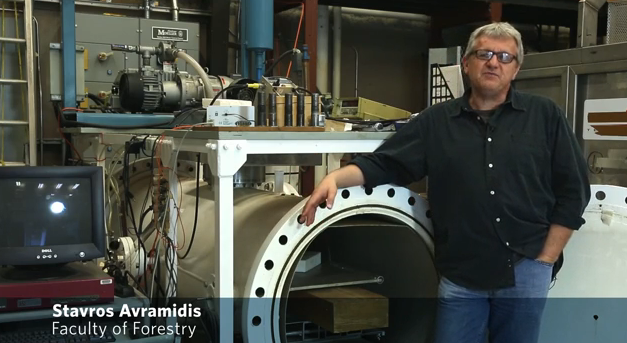

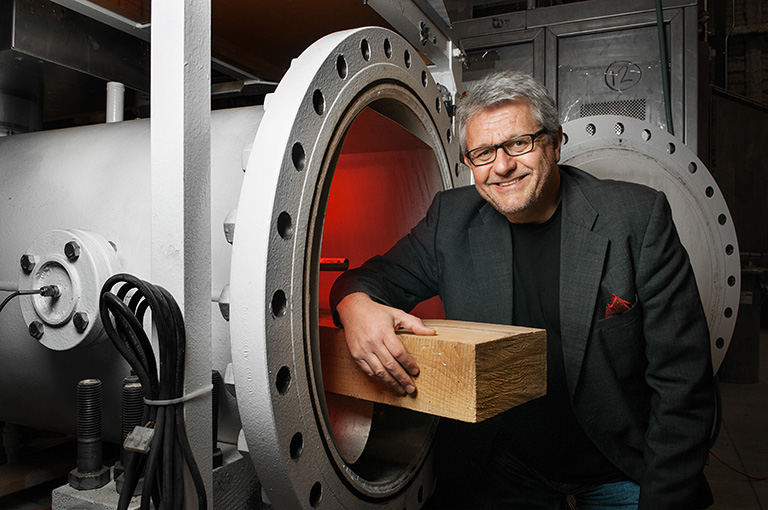

In 2013 the UN banned the use of toxic methyl bromide with no real chemical alternative available. Irradiation works but it’s expensive and carries a ‘stigma’, explains Stavros Avramidis, professor of Wood Science in the UBC Faculty of Forestry: “The only thing left in your arsenal is thermal treatment.”

But just not any type of thermal treatment. Kiln drying is handling intensive and thus expensive. It also dries out and hardens fresh wood, as does pasteurization, steaming the wood in its own juices. “We don’t want to take the water out,” says Avramidis. “We want to sell it with the water in. . . . So we have to figure out another way of doing that.”

Avramidis’s solution: ‘radio-frequency’ or ‘dielectric’ heating that uses electro-magnetic energy to ‘zap’ the wood – but not just with any frequencies. Microwaves are familiar technology but have trouble penetrating dense material such as wood and thus risks leaving ‘cold spots’ or bug-friendly havens.

Avramidis has a better way: blast the wood – and whatever lies within – with high-energy radio waves in the same frequency ranges that carry popular AM music – but with a very different targeted audience.

Call it poplar music, killer tunes, Radio Free Fibre; the longer-wave radio waves penetrate deeply, quickly and apparently in terms of bugs and phyto-sanitation, fatally. Regardless of the wood’s thickness, the treatment takes just two to three hours and doesn’t compromise the wood or its moisture content.

The UBC research was backed by an NSERC Strategic Project Grant. The FAO is in the process of approving the dielectric heating technique for processed and dry wood. However, green wood is another matter. The approval process is lengthy and must be approved by member countries worldwide.

As the world waits, Avramidis is literally fine-tuning the process, writing a procedural manual for future operators in anticipation of the FAO okay for green wood – and what will be a very bad day for bugs.

Read more about

SustainabilityThis story also illustrates our commitment to:

Research ExcellenceRelated Content

“The only thing left in your arsenal is thermal treatment.”

Campus

Vancouver